Ngwa na Semiconductor Industry

GREEN bụ ụlọ ọrụ teknụzụ dị elu nke mba raara nye R&D na imepụta mgbakọ elektrọnik akpaaka na nkwakọ ngwaahịa semiconductor & akụrụngwa nnwale. Ijere ndị isi ụlọ ọrụ ozi dị ka BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, na ụlọ ọrụ 20+ ndị ọzọ Fortune Global 500. Onye mmekọ ntụkwasị obi gị maka ngwọta nrụpụta dị elu.

Igwe eji ejikọta ọnụ na-eme ka micro-interconnects na dayameta waya, na-ahụ na iguzosi ike n'ezi ihe mgbaàmà; formic acid vacuum soldering na-emepụta nkwonkwo a pụrụ ịdabere na ya n'okpuru ọdịnaya oxygen <10ppm, na-egbochi ọdịda oxidation na nkwakọ ngwaahịa dị elu; AOI na-egbochi ntụpọ micron-ọkwa. Mmekọrịta a na-eme ka ọ bụrụ> 99.95% nkwakọ ngwaahịa dị elu, na-ezute oke nnwale nke ibe 5G/AI.

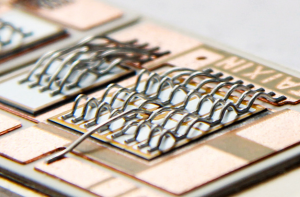

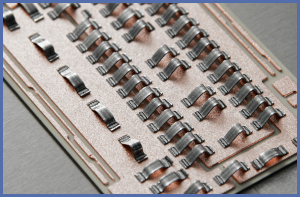

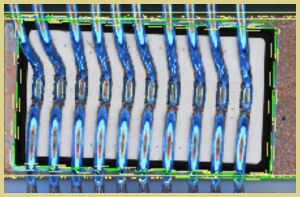

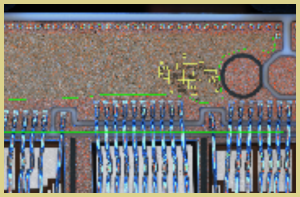

Ultrasonic Wire Bonder

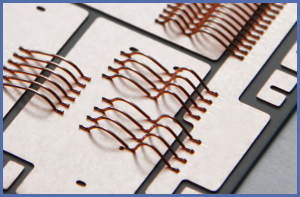

Ike ijikọ 100 μm-500 μm waya aluminum, 200 μm-500 μm ọla kọpa waya, aluminum ribbons ruo 2000 μm n'obosara na 300 μm oké, yana ọla kọpa ribbons.

Oke njem: 300 mm × 300 mm, 300 mm × 800 mm (nke a na-emezi), yana nkwugharị <± 3 μm

Oke njem: 100 mm × 100 mm, nwere ike ikwugharị <±3 μm

Kedu ihe bụ Wire Bonding Technology?

Njikọ waya bụ usoro njikọ njikọta nke microelectronic eji jikọọ ngwaọrụ semiconductor na nkwakọ ngwaahịa ma ọ bụ ihe ha. Dị ka otu n'ime teknụzụ kachasị dị oke egwu na ụlọ ọrụ semiconductor, ọ na-enyere aka ịmekọrịta mgbawa na sekit mpụga na ngwaọrụ eletrọnịkị.

Ngwa ejikọ waya

1. Aluminom (Al)

Igwe ọkụ eletrik dị elu vs. ọla edo, ọnụ ahịa dị irè

2. Ọla kọpa (Cu)

25% eletriki/ọkụ ọkụ dị elu karịa Au

3. Gold (Au)

conductivity kacha mma, nguzogide corrosion na ntụkwasị obi njikọ

4. Ọlaọcha (Ag)

conductivity kacha elu n'etiti ọla

Aluminom waya

Aluminom Ribbon

Waya ọla kọpa

Ọla kọpa Ribbon

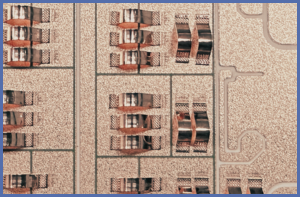

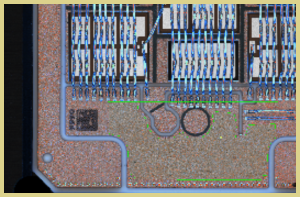

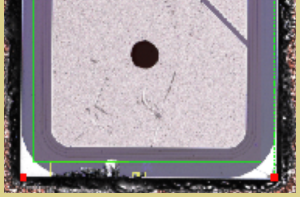

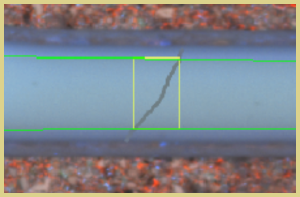

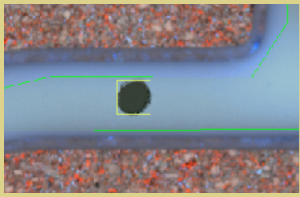

Semiconductor Die Bonding & Wire Bonding AOI

Na-eji igwefoto ụlọ ọrụ 25-megapixel chọpụta ihe mgbakwunye anwụ na ntụpọ njikọ waya na ngwaahịa ndị dị ka ICs, IGBTs, MOSFETs, na okpokolo agba, na-enweta ọnụọgụ nchọpụta ntụpọ karịrị 99.9%.

Ọnọdụ nyocha

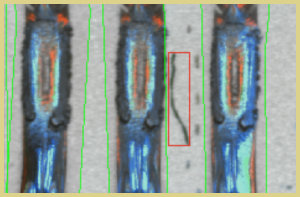

Nwere ike inyocha mgbawa ịdị elu na ịdị larịị, mgbawa mgbawa, tilt, na chipping; solder bọọlụ na-abụghị adhesion na solder nkwonkwo detachment; ntụpọ njikọ waya gụnyere oke akaghị ogologo ma ọ bụ ezughi oke, mgbaka loop, wires gbajiri agbaji, wires na-efu efu, kọntaktị waya, ịgbado waya, ngafe akaghị, na ogologo ọdụ dị oke; ezughị ezu nrapado; na metal splatter.

Bọọlụ solder/ fọdụrụ

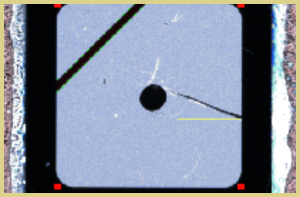

Chip Scratch

Ndokwa mgbawa, akụkụ, tilt Meas

Ihe Mmetọ Chip/Ihe Ndị Mba Ọzọ

Chipping

Ceramic trenchi mgbawa

Ceramic Trench Mmetọ

AMB oxidation

Igwe ọkụ na-emegharị Formic Acid In-Line

1. Okpomọkụ kachasị ≥ 450 ° C, ọkwa oghere kacha nta <5 Pa

2. Na-akwado formic acid na nitrogen usoro gburugburu

3. Ọnụ ọgụgụ efu efu ≦ 1%, ọnụ ọgụgụ efu efu ≦ 2%

4. Mmiri jụrụ oyi + nitrogen dị jụụ, nke nwere usoro mmiri na-ekpo ọkụ na kọntaktị jụrụ oyi

Semiconductor ike IGBT

Ọnụego mkpofu karịrị akarị na ire ere IGBT nwere ike ịkpalite ọdịda nke agbụ-mmeghachi omume gụnyere mgbapụ ọkụ, mgbawa igwe, na mmebi arụmọrụ eletrik. Mbelata ọnụego efu ka ọ bụrụ ≤1% na-eme ka ntụkwasị obi ngwaọrụ dịkwuo elu yana ịrụ ọrụ ike.

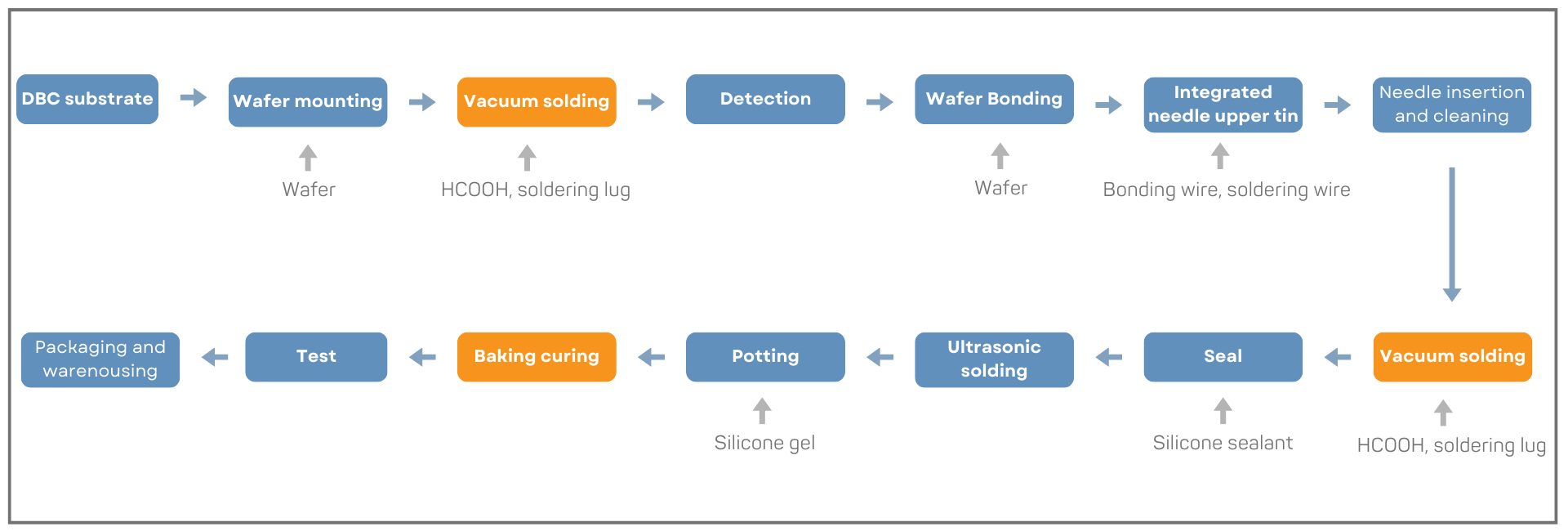

IGBT mmepụta usoro usoro