Igwe mgbasa ozi Robot anọ nwere akụkụ anọ

Oke ngwaọrụ

| ihe | Nkọwapụta |

| Nlereanya | GR-XFSZ600/GR-XFSZ800 |

| Robot iru | 600mm / 800mm |

| Aha ika | GREEN |

| Okwu | igwe ịghasa |

| Nri osisi strok | 500mm / 800mm |

| Nha (L*W*H) | 1300*1000*1950mm/1500*1200*1950mm |

| Ike nchekwa mmemme | 0-1200 mm / s |

| Axis ije ọsọ | 999 otu |

| Mkpọchi arụmọrụ | otu ịghasa bụ banyere 2.0-2.5S |

| Mkpọchi mkpọchi | 99.98% |

| Ọkụ ọkụ na-arụ ọrụ | AC220V |

| Isi iyi ikuku na-arụ ọrụ | 0.4-0.7MPa |

| ike | Ihe dịka 1.5KW |

Atụmatụ ngwaọrụ

1.Stand-naanị offline Ọdịdị, na nri n'elu ikpo okwu na-akpali ịghọta ngwaahịa nri / igbasa, na thefour-axis robot linkage ghọtara ịghasa mkpọchi.

2.IPC ngagharị njikwa usoro, visual mmemme, na-akparaghị ókè data ịzọpụta;

3.Graphical ngosi nke mkpọchi isi na mkpọchi results, akpaaka marking nke OK / NG ịghasa ihe, kensinammuo na ngwa ngwa search;

4.Multi-user,multi-level ikike njikwa, nchịkwa nwere ike ịmepụta akaụntụ ọhụrụ na-ekenye softwareoperation ikike.

5.CCD na-enyere aka nkuzi ịghasa nhazi ihe iji kpochapụ njehie nrụnye visual ntuziaka;CCD visual n'ọnọdu mgbazi nhazi ihe, ọgụgụ isi Nchikota mgbazi nke otutu otu nke Mark ihe, Mma mbụ-agafe ọnụego nke foto;

6.Support nchọpụta mkpu dị ka mgbachi na-agbachi agbachi, ezé na-amị amị, na-ese n'elu na ihe ndị ọzọ. The software na-abịa na a sere n'elu elu ịrụzi ọrụ;

7.7.Z-axis nwere ike kwadebere na laser displacement sensọ (ese n'elu elu nha), downforce nchọpụta ihe mmetụta (nhọrọ);

8.The electric batch nwere ike kwadebere na HIOS electric batch, Qili ọsọ electric ogbe, servo electric ogbe, ọgụgụ isi electric ogbe, wdg (nhọrọ);

9.The akụrụngwa nwere ike bulite MES dị ka ahịa mkpa, dị ka torque, ọnụ ọgụgụ nke ntụgharị, angle, torque curve eserese, na mkpọchi ọnọdụ.

10.Manual koodu nyocha na akpaka koodu scanning nwere ike họrọ (nhọrọ)

11.Production data nwere ike ịchọta, na ngwanrọ na-abịa na njikwa njikwa kanban. Enwere ike ibugo ma budata ụdị data niile (nhọrọ); 12.Automatic torque spot check,chekwa na torque ntụpọ nlele nsonaazụ na ike ajụjụ (nhọrọ).

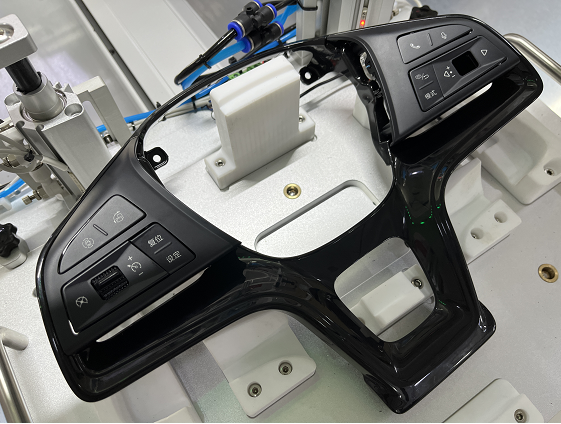

Gosi nkọwa